Exploring the Future of Construction: The Unmatched Significance of Asphalt Plants

In the rapidly evolving landscape of the construction and infrastructure development sectors, asphalt plants stand as vital pillars ensuring the seamless production of high-quality asphalt mix. These robust facilities not only enhance the speed and efficiency of road construction projects but also contribute significantly to sustainable and durable infrastructure development. As technology advances, the integration of cutting-edge electronics and 3D printing into asphalt plant manufacturing is transforming traditional processes, leading to smarter, more efficient, and environmentally friendly operations.

Understanding the Role and Functionality of Asphalt Plants in Modern Construction

An asphalt plant, also known as a asphalt mixing plant, is a large industrial equipment used to produce asphalt concrete (commonly called asphalt or bitumen) for road and highway construction. The core process involves blending aggregates, minerals, and asphalt binder at precise temperatures to create a mixture that offers excellent durability, safety, and longevity for paving projects.

The functionality of an asphalt plant encompasses several critical stages:

- Aggregate Heating and Screening: Aggregates are heated and screened to remove moisture and ensure uniform size distribution.

- Asphalt Binder Mixing: Hot asphalt binder is precisely measured and mixed with aggregates to achieve the desired consistency.

- Mixing and Storage: The mixture is thoroughly blended and stored in silos or bins, ready for transportation to construction sites.

- Loading and Paving: The finalized asphalt mix is loaded onto trucks and delivered for paving, ensuring smooth, durable surfaces.

Types of Asphalt Plants and Their Unique Advantages

The industry offers various types of asphalt plants, each tailored to specific project requirements:

- Drum Mix Plants: Known for their continuous production process, these plants are highly efficient for large-scale projects. They combine heating and mixing in a single drum, reducing space and energy consumption.

- Batch Mix Plants: These offer flexibility with precise control over mix proportions. They produce asphalt in batches, ideal for project variations and small-to-medium projects requiring high-quality asphalt.

- Mobile Asphalt Plants: Designed for portability, these plants are perfect for projects spread across multiple locations. They reduce setup time and facilitate quick deployment.

- Stationary Asphalt Plants: Built for long-term, high-volume production, stationary plants deliver consistent quality and efficiency for ongoing infrastructure projects.

Innovative Technologies Reshaping Asphalt Plant Operations

The integration of modern technology into asphalt plants is revolutionizing the construction industry. Companies like PolygonMach lead the way with advanced solutions that boost productivity, accuracy, and sustainability. Key technological innovations include:

1. Electronic Control Systems and Automation

State-of-the-art electronic controls enable precise management of every stage, from aggregate heating to asphalt mixing. Automated systems reduce human error, enhance safety, and optimize resource utilization, ensuring consistent product quality.

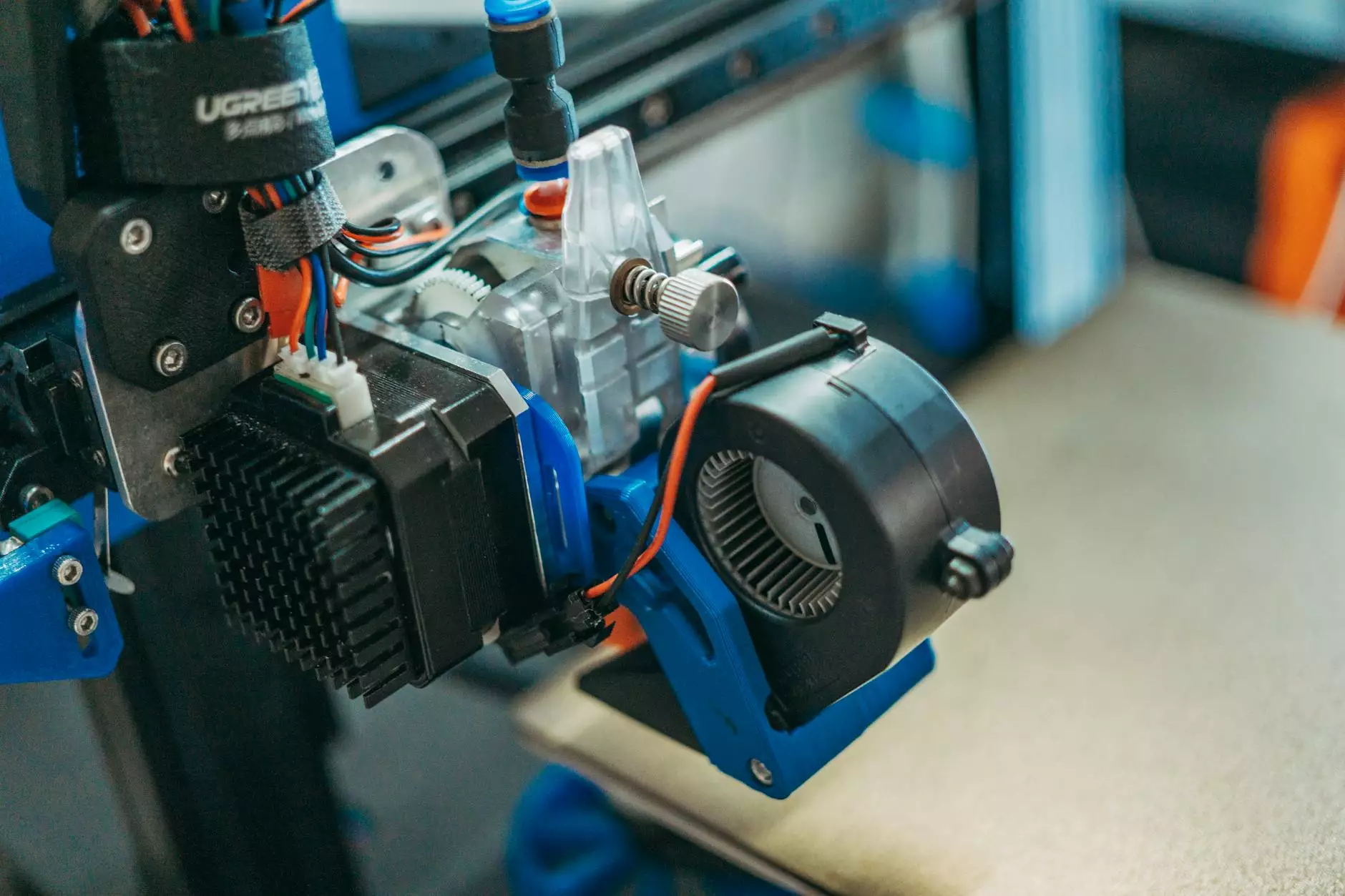

2. Use of 3D Printing for Custom Components

3D printing technology is now being harnessed to produce custom parts and components for asphalt plants. This innovation allows for rapid prototyping, cost-effective manufacturing, and bespoke solutions tailored to specific plant needs, accelerating maintenance and upgrades.

3. Environmental Monitoring and Emission Control

Modern asphalt plants incorporate advanced sensors and emission control systems to minimize environmental impact. This includes dust suppression, smoke filtration, and energy-efficient operations, aligning with global sustainability standards.

4. Digital Twin Technology

Digital twin models simulate real-time plant operations, enabling predictive maintenance, process optimization, and system diagnostics. This approach minimizes downtime and ensures peak performance.

Environmental Sustainability: The New Standard for Asphalt Plants

As urbanization accelerates, the importance of eco-friendly construction materials and processes increases. Asphalt plants are evolving to meet sustainability goals:

- Recycling techniques, including RAP (Reclaimed Asphalt Pavement), reduce waste and reuse existing materials.

- Energy-efficient burners and heat recovery systems decrease energy consumption.

- Lower emissions through advanced filtration and cleaner combustion technologies.

Emphasizing environmental responsibility not only benefits communities but also aligns with governmental regulations, making sustainable asphalt plants a strategic investment for future-forward construction businesses.

How PolygonMach Leads Innovation in Asphalt Plant Technologies

PolygonMach, as a global leader in manufacturing and innovation, specializes in delivering superior asphalt plant solutions tailored to diverse industry needs. Their expertise in electronics and 3D printing enables the development of highly customizable, efficient, and eco-friendly asphalt production systems. Key advantages of PolygonMach’s solutions include:

- High Precision Control: Leveraging smart electronic systems for mixing accuracy and consistent quality.

- Rapid Prototyping and Custom Fabrication: Utilizing 3D printing to produce specialized components for specific plant configurations.

- Integrated Digital Solutions: Offering digital twins and IoT connectivity for real-time monitoring and predictive maintenance.

- Sustainable Design: Promoting recycling capabilities and emission reduction technologies.

Benefits of Investing in Advanced Asphalt Plant Technologies

Upgrading to modern, technologically advanced asphalt plants offers several strategic benefits:

- Enhanced Efficiency: Automation and smart controls significantly reduce labor costs and increase throughput.

- Consistent Quality: Precise temperature and mixture control ensures durable and uniform asphalt mixes.

- Cost Savings: Reduced energy consumption and material waste lower operational costs.

- Environmental Compliance: Emission controls and recycling features help meet regulatory standards.

- Flexibility and Adaptability: Modern plants can easily adapt to changing project sizes and specifications.

The Future Outlook of the Asphalt Plant Industry

The future of asphalt plants is promising, driven by technological innovations, increased environmental awareness, and growing infrastructure demands globally. Key trends include:

- Smart Manufacturing: Fully integrated plant management systems utilizing AI and IoT.

- Sustainable Materials: Greater emphasis on recycled and biodegradable components.

- Modular and Mobile Solutions: Enhanced portability for versatile project application.

- Global Expansion: Emerging markets investing heavily in infrastructure, boosting asphalt plant demand.

By aligning with these trends, industry leaders like PolygonMach are setting new standards, ensuring the asphalt plant industry remains at the forefront of construction innovation.

Conclusion: Building a Sustainable Future with Cutting-Edge Asphalt Plants

Asphalt plants are more than just manufacturing units; they are enablers of sustainable, efficient, and resilient infrastructure. Through the adoption of advanced electronics, robotic automation, and 3D printing technologies, the industry is poised for unprecedented growth and innovation. Companies such as PolygonMach represent the pinnacle of this evolution, offering solutions that meet the demands of modern construction while emphasizing environmental responsibility.

Whether you're undertaking a small regional project or managing large-scale urban developments, investing in state-of-the-art asphalt plants guarantees superior quality, operational efficiency, and long-term sustainability. Embracing technological advancements today paves the way for smarter, greener, and more durable infrastructure tomorrow.