Revolutionizing Urban Maintenance with Advanced 3D Printing Technologies in Street Sweeping Machines

In the bustling landscape of modern cities, maintaining clean, safe, and environmentally friendly streets has become a top priority for urban planners and municipal authorities alike. The backbone of effective street cleaning systems is the innovative street sweeping machines, which play a pivotal role in ensuring sanitation, reducing pollution, and enhancing the overall quality of urban life.

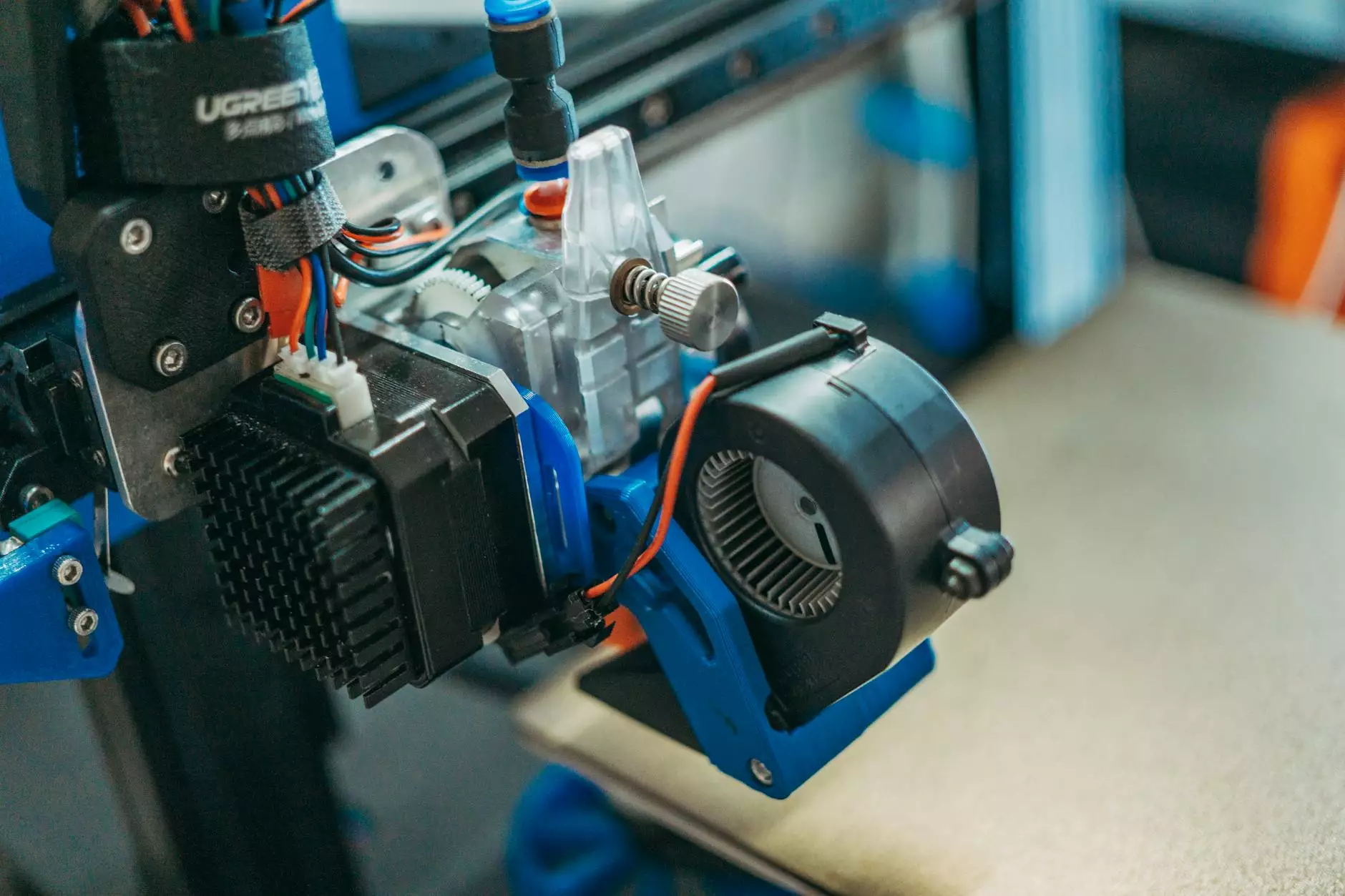

At ceksansweepers.com, we harness the powerful capabilities of 3D printing technology to develop, design, and produce cutting-edge components for street sweeping machines. Our expertise unlocks unprecedented levels of customization, durability, and efficiency, setting new standards in the industry. This article explores how 3D printing is transforming the construction and functionality of street sweeping machines and what future innovations hold for urban sanitation.

Understanding the Role of Street Sweeping Machines in Modern Urban Environments

Street sweeping machines are essential tools designed to proactively manage urban cleanliness. These machines perform several critical functions, including:

- Debris and litter removal from streets, sidewalks, and parking lots

- Dust suppression to improve air quality

- Pollutant filtration by capturing contaminants such as oil, chemicals, and heavy metals

- Maintaining traffic safety through cleaner surfaces

- Preventing water runoff pollution during rainy weather

Modern street sweeping machines are designed for flexibility, efficiency, and minimal environmental impact. They often feature advanced navigation systems, eco-friendly engines, and ergonomic designs derived from innovative manufacturing techniques, including 3D printing.

The Evolution of Component Manufacturing in Street Sweeping Machines

Traditional manufacturing methods like casting, machining, and injection molding have historically been used to produce parts for street sweeping machinery. However, these processes pose limitations in manufacturing speed, customization, and cost efficiency, especially for complex or bespoke components.

This is where 3D printing (additive manufacturing) has revolutionized the industry. It enables rapid prototyping, precise customization, and on-demand part production—particularly vital for components exposed to high wear and environmental stress.

How 3D Printing Enhances Street Sweeping Machines Performance

By integrating 3D printing in the development cycle, manufacturers like Ceksansweepers.com craft components that exhibit higher strength-to-weight ratios, superior flexibility, and increased corrosion resistance. Below are some specific advantages:

1. Lightweight Yet Strong Components

Using specific materials such as reinforced thermoplastics and metal powders, 3D printing produces parts that are significantly lighter than traditionally manufactured counterparts. This reduction in weight leads to increased fuel efficiency and better maneuverability of street sweeping machines.

2. Rapid Prototype Development and Testing

Prototyping is expedited dramatically, allowing quick iteration and testing. This speeds up the development cycle, reduces costs, and introduces innovations faster into the market.

3. Customization and Complex Geometries

3D printing enables the fabrication of complex geometries that are impossible or costly to produce with conventional methods. This results in highly specialized parts for specific urban environments or specialized functions, such as adaptive brushes or modular debris containers.

4. On-Demand Spare Parts Production

Manufacturers can produce spare parts as needed, reducing inventory costs and downtime for maintenance. This flexibility ensures street sweeping machines stay operational with minimal delays.

Innovative Applications of 3D Printing in Street Sweeping Machines

Within the industry, 3D printing is used to develop various critical components:

- Gear and pulley systems: Complex geometries reduce weight while increasing durability.

- Housings and covers: Customized to fit specific models and operational environments.

- Brush attachments and nozzles: Designed for enhanced debris collection and fluid flow.

- Sensor and electronic mounts: Securely hold modern navigation and pollution detection devices.

- Wear-resistant parts: Made from composite materials to withstand abrasive conditions.

Benefits of Incorporating 3D Printing into Street Sweeping Machines Manufacturing

The integration of 3D printing offers manifold benefits:

- Cost Reduction: Lower tooling and labor costs for small batch runs and custom components.

- Faster Turnaround: Transition from concept to functional part occurs within days, not weeks.

- Enhanced Innovation: Creative designs and complex geometries lead to superior functional performance.

- Sustainability: Less waste generated during production, supporting eco-friendly manufacturing practices.

- Personalization: Tailoring street sweeping machines to specific operational needs and environmental conditions.

The Future of Street Sweeping Machines Powered by 3D Printing

As urban environments grow smarter and more sustainable, street sweeping machines will continue to evolve through technological integration. The future includes:

- Fully automated, autonomous street sweepers with modular parts produced via 3D printing, facilitating quick upgrades and repairs.

- Use of eco-friendly and recycled materials in 3D printing processes, aligning with green initiatives.

- Smart components embedded with sensors and IoT capabilities, enhancing precision and operational efficiency.

- Enhanced durability with advanced composite materials, extending the lifespan of crucial parts.

Such innovations will not only improve cleaning efficiency but will also significantly reduce operational and maintenance costs for cities and companies implementing these advanced solutions.

Choosing the Right Partner for 3D Printed Components in Street Sweeping Machines

When searching for a reliable provider of 3D printing solutions for street sweeping machines, it is vital to consider experience, materials used, customization options, and industry reputation. Ceksansweepers.com has established itself as a leader in providing innovative, high-quality 3D printed components specifically tailored for the demanding urban sanitation industry.

Conclusion: Embracing the Power of 3D Printing in Urban Cleanliness

In the dynamic realm of urban sanitation, street sweeping machines are essential for maintaining clean, healthy, and sustainable cities. The advent of 3D printing technology has opened a new frontier in designing and manufacturing these vital machines, offering unmatched advantages in customization, durability, cost-efficiency, and environmental responsibility.

Choosing a forward-thinking partner like Ceksansweepers.com allows municipalities and companies to leverage the latest innovations, ensuring their street cleaning operations are more effective than ever before. Embrace the future of urban sanitation with 3D printed street sweeping machines—where technology meets cleanliness for smarter cities worldwide.